In industrial environments where airborne particulates are prevalent—such as feed mills, cement plants, flour factories, and woodworking facilities—monitoring dust concentration is critical for ensuring worker safety and environmental compliance. Laser dust sensors have emerged as indispensable tools in these settings, providing real-time data on particulate matter (PM) levels. This article delves into the measurement methods of laser dust sensors, their significance in industrial applications, and the standards governing their use.

Laser dust sensors operate on the principle of light scattering. When a laser beam passes through an air sample containing dust particles, the particles scatter the light. The intensity and pattern of this scattered light are detected by photodetectors positioned at specific angles. By analyzing these signals, the sensor calculates the concentration of particulate matter in the air.

The primary types of particulate matter measured include:

PM2.5: Particles with diameters less than 2.5 micrometers.

PM10: Particles with diameters less than 10 micrometers.

Total Suspended Particulates (TSP): A broader category encompassing particles of various sizes.

These measurements are crucial for assessing air quality and ensuring that particulate levels remain within safe limits.

The accuracy and reliability of dust measurements are paramount, especially in environments where dust accumulation can pose health risks or explosion hazards. Several methods are employed to measure particulate concentrations:

Gravimetric Method: Considered the reference method, it involves collecting particles on a filter and weighing them.

Beta-ray Absorption Method: Measures the attenuation of beta radiation through a particle-laden filter.

Micro-oscillating Balance Method: Detects mass changes using a vibrating element.

Light Scattering Method: Utilizes laser technology to detect scattered light from particles.

In China, the Ministry of Environmental Protection has established standards for these measurement methods. For instance, the HJ618-2011 standard outlines the gravimetric method for determining ambient air PM10 and PM2.5 concentrations. Other standards, such as HJ653-2013 and HJ655-2013, provide technical specifications for continuous automatic monitoring systems using beta-ray absorption and micro-oscillating balance methods. The light scattering method, while cost-effective and suitable for portable devices, is sensitive to environmental factors and is specified in the QX/T173-2012 standard by the China Meteorological Administration.

Ensuring accurate readings from dust monitors is essential for effective air quality control, especially in industrial environments where particulate matter poses health and safety risks. Calibration is a key process that maintains the accuracy of these instruments by aligning their readings with certified reference standards. Over time, external environmental factors such as temperature, humidity, and airborne contaminants can cause sensor drift, leading to inaccurate measurements. Regular calibration corrects these deviations, ensuring that data remains reliable and actionable.

Accurate dust monitoring is critical for regulatory compliance, workplace safety, and maintaining a healthy environment. Misleading data due to uncalibrated equipment can result in improper responses, putting workers at risk and potentially violating environmental standards. To calibrate a dust monitor, technicians compare its readings against a certified reference instrument under controlled conditions and adjust the output accordingly.

Manufacturers typically recommend calibration intervals of every 6 to 12 months, depending on the operating environment and usage intensity. Following these guidelines helps extend the sensor’s life and ensures consistent performance. In high-risk or high-precision applications, more frequent calibration may be necessary. Ultimately, routine calibration is an investment in safety, regulatory compliance, and the long-term reliability of your dust monitoring system.

Real-time monitoring of dust concentrations is vital for several reasons:

Health Protection: Prolonged exposure to high levels of fine dust can lead to respiratory issues and other health problems.

Explosion Prevention: Certain dusts, when suspended in air at specific concentrations, can become explosive. Real-time monitoring helps in maintaining dust levels below explosive thresholds.

Regulatory Compliance: Industries must adhere to environmental and occupational safety regulations that stipulate permissible dust concentration levels.

Advanced laser dust sensors can trigger alarms when dust concentrations approach hazardous levels, enabling prompt corrective actions.

Combustible dust explosions are a significant concern in various industries. When fine particles are suspended in the air within a confined space and encounter an ignition source, they can cause rapid combustion, leading to explosions. The Occupational Safety and Health Administration (OSHA) identifies several materials that can form combustible dust, including:

Food products (e.g., sugar, flour, grain)

Wood and paper products

Metals (e.g., aluminum, magnesium)

Chemicals and pharmaceuticals

To mitigate these risks, industries must implement comprehensive dust control measures, including regular cleaning, proper ventilation, and the use of explosion-proof equipment.

Choosing an appropriate dust sensor involves considering various factors:

Environmental Conditions: Sensors must withstand the specific conditions of the facility, such as temperature, humidity, and potential exposure to corrosive substances.

Measurement Range and Sensitivity: The sensor should accurately detect the range of particle sizes and concentrations relevant to the facility's operations.

Compliance Requirements: Sensors should meet the regulatory standards applicable to the industry and region.

Maintenance and Calibration: Consider the ease of maintenance and the frequency of calibration required to ensure ongoing accuracy.

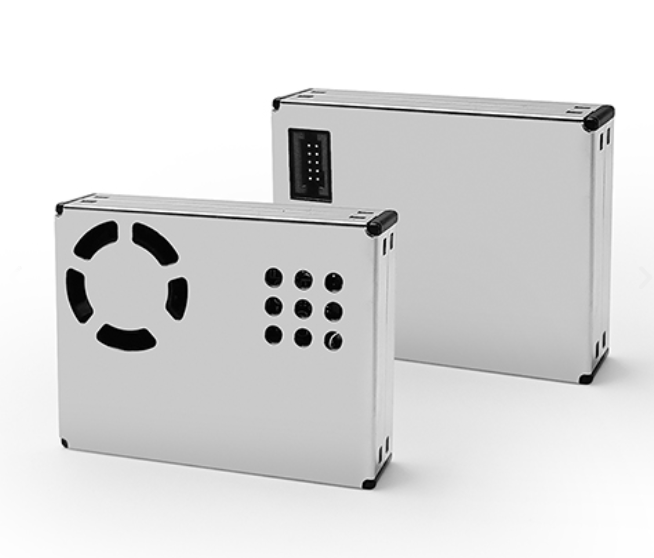

For environments with explosion risks, it's crucial to select sensors that are certified as explosion-proof. For instance, MoistTech offers explosion-proof enclosures for their sensors, providing protection in hazardous conditions.

Laser dust sensors play a pivotal role in maintaining safe and compliant industrial environments. By providing real-time data on particulate concentrations, they enable proactive measures to protect worker health, prevent explosions, and adhere to environmental regulations. Selecting the right sensor, tailored to the specific needs and conditions of the facility, is essential for effective dust monitoring and control.

Previous: Wired vs. Wireless Air Quality Monitors: Which is Right for Your Building?