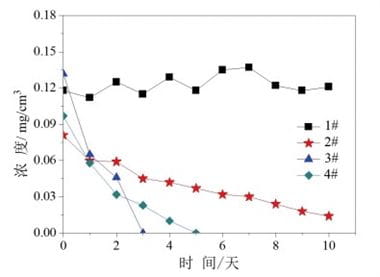

Therefore, for the formaldehyde sensor in this study, the influence of high temperatures on the sensor is very limited. In the actual transportation, storage or working process of the air conditioner, the sensor can ensure the reliability of continuous operation and storage under extremely high temperatures. For the current commercial formaldehyde sensors 2#, 3#, and 4#, traditional liquid acid-base electrolytes are used as proton conduction media. Under high temperatures, the water in the electrolyte is easily lost, which leads to an increase in the system concentration. As a result, the ability of the electrolyte system to conduct protons gradually deteriorates, or even loses its ability to conduct protons. At the same time, at a long-term high temperature, the reactivity of the internal catalyst material may be seriously damaged. The above problems will eventually cause sensors 2#, 3# and 4# to be unable to resist the destructive effect of the external high-temperature environment. The sensor 1# in this study adopts a new type of electrolyte system, which is different from the current traditional electrolyte system. It has excellent thermal stability and chemical stability, and moisture can be effectively and stably confined in the electrolyte system. After treatment at a high temperature, the ability of the electrolyte system to conduct protons will not be destroyed. Therefore, compared with the current commercial sensors 2#, 3#, and 4#, the formaldehyde sensor 1# in this study has the characteristics of high-temperature resistance at 70°C, which lays the foundation for ensuring its application in the air conditioner.

Figure 1 High-temperature decay curve of sensors

3.2 Anti-alcohol interference tests

In order to verify that the sensor can resist the false detection and false alarm caused by family life, the anti-interference ability of the sensor to continuously work under the environmental conditions with interference sources is reflected by simulating the scene of drinking in a family gathering for a long time. The formaldehyde concentration output result of the sensor is shown in Figure 2; the anti-alcohol interference experiment was carried out in a user's home with an area of 70m2, and its distributions of internal layout and test point are shown in Figure 3.

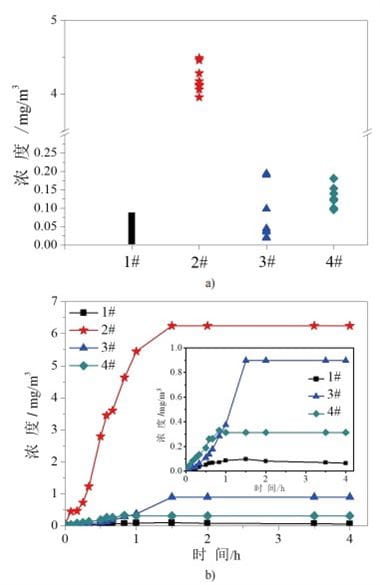

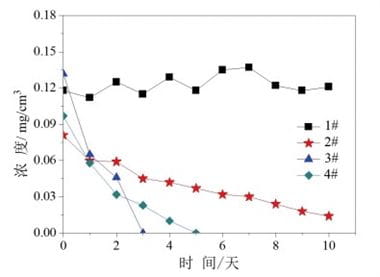

Figure 2 The formaldehyde concentration output of the sensor in the anti-alcohol interference experiment

Figure 3 The distribution of home interior layouts and test points

Figure 2a is the output of the sensor's anti-alcohol interference performance in an experimental chamber with an area of 30m3 by creating an environment with 10 ppm alcohol to simulate a drinking scene. Through comparison, it is found that in the atmosphere of 10 ppm alcohol, the commercial formaldehyde sensor 2# is seriously bursting, and the displayed formaldehyde concentration is 4 to 5 mg/m3, far exceeding the national standard safety line of 0.1 mg/m3. The formaldehyde concentration output by commercial formaldehyde sensors 3# and 4# also reaches 0.1 to 0.2 mg/m3, which exceeds the national standard safety line, that is to say, under a certain alcohol concentration environment, the currently commercialized formaldehyde sensors 2#, 3#, and 4# are weak in resisting alcohol interference. When they are applied to air conditioners, there will be obvious false detections and false alarms. For the formaldehyde sensor 1# based on the new electrolyte and anti-interference catalyst slurry formulation in this study, under the atmosphere of 10 ppm alcohol, the formaldehyde concentration of the formaldehyde sensor is less than 0.1 mg/m3, which is lower than the national standard safety line, and the anti-alcohol interference is less than 1%.

At the same time, the scenario of drinking for 4 hours is further simulated in the user's home to verify the anti-interference ability of each sensor, as shown in Figure 2b. The formaldehyde sensor 2# is still seriously bursting, and the formaldehyde concentration output by formaldehyde sensors 3# and 4# also reaches 0.15 to 0.35 mg/m3, which exceeds the national standard safety line. However, the concentration output of the formaldehyde sensor 1# in this study is less than 0.05 mg/m3 in the long-term range, which is significantly lower than the national standard safety line. It has good resistance to alcohol interference. It can be applied to air conditioners, which will effectively reduce the probability of false detection and false alarms and improve the user experience. The above differences in anti-interference ability are mainly caused by the highly selective active composition of the multi-precious metal system in the catalyst slurry formulation designed in this study, which can significantly reduce the adsorption and chemical action of alcohol molecules, thereby showing excellent anti-alcohol interference ability.

Figure 1 High-temperature decay curve of sensors

3.2 Anti-alcohol interference tests

In order to verify that the sensor can resist the false detection and false alarm caused by family life, the anti-interference ability of the sensor to continuously work under the environmental conditions with interference sources is reflected by simulating the scene of drinking in a family gathering for a long time. The formaldehyde concentration output result of the sensor is shown in Figure 2; the anti-alcohol interference experiment was carried out in a user's home with an area of 70m2, and its distributions of internal layout and test point are shown in Figure 3.

Figure 2 The formaldehyde concentration output of the sensor in the anti-alcohol interference experiment

Figure 3 The distribution of home interior layouts and test points

Figure 2a is the output of the sensor's anti-alcohol interference performance in an experimental chamber with an area of 30m3 by creating an environment with 10 ppm alcohol to simulate a drinking scene. Through comparison, it is found that in the atmosphere of 10 ppm alcohol, the commercial formaldehyde sensor 2# is seriously bursting, and the displayed formaldehyde concentration is 4 to 5 mg/m3, far exceeding the national standard safety line of 0.1 mg/m3. The formaldehyde concentration output by commercial formaldehyde sensors 3# and 4# also reaches 0.1 to 0.2 mg/m3, which exceeds the national standard safety line, that is to say, under a certain alcohol concentration environment, the currently commercialized formaldehyde sensors 2#, 3#, and 4# are weak in resisting alcohol interference. When they are applied to air conditioners, there will be obvious false detections and false alarms. For the formaldehyde sensor 1# based on the new electrolyte and anti-interference catalyst slurry formulation in this study, under the atmosphere of 10 ppm alcohol, the formaldehyde concentration of the formaldehyde sensor is less than 0.1 mg/m3, which is lower than the national standard safety line, and the anti-alcohol interference is less than 1%.

At the same time, the scenario of drinking for 4 hours is further simulated in the user's home to verify the anti-interference ability of each sensor, as shown in Figure 2b. The formaldehyde sensor 2# is still seriously bursting, and the formaldehyde concentration output by formaldehyde sensors 3# and 4# also reaches 0.15 to 0.35 mg/m3, which exceeds the national standard safety line. However, the concentration output of the formaldehyde sensor 1# in this study is less than 0.05 mg/m3 in the long-term range, which is significantly lower than the national standard safety line. It has good resistance to alcohol interference. It can be applied to air conditioners, which will effectively reduce the probability of false detection and false alarms and improve the user experience. The above differences in anti-interference ability are mainly caused by the highly selective active composition of the multi-precious metal system in the catalyst slurry formulation designed in this study, which can significantly reduce the adsorption and chemical action of alcohol molecules, thereby showing excellent anti-alcohol interference ability.

Previous: Research on the Application of Formaldehyde Sensors to Air Conditioning (Part One)

Next: Research on the Application of Formaldehyde Sensors to Air Conditioning (Part Three)