3.3 Simulation scene experiment

To verify that the sensor element can withstand the extreme changes in environmental conditions during use, the aging experiments of the accelerated sensor device are simulated through low-temperature experiments, high and low-temperature shocks, steady-state damp heat, drop and sweep vibration and other common scene experiments to reflect reliability, and packaging quality of sensors and internal components under continuous or transient environmental conditions. The experimental results are shown in Table 1.

Table 1 Concentration changes of sensors before and after experiments in each simulation scene

To verify that the sensor element can withstand the extreme changes in environmental conditions during use, the aging experiments of the accelerated sensor device are simulated through low-temperature experiments, high and low-temperature shocks, steady-state damp heat, drop and sweep vibration and other common scene experiments to reflect reliability, and packaging quality of sensors and internal components under continuous or transient environmental conditions. The experimental results are shown in Table 1.

Table 1 Concentration changes of sensors before and after experiments in each simulation scene

| 1# | 2# | 3# | 4# | |||||

| Before the experiment | After the experiment | Before the experiment | After the experiment | Before the experiment | After the experiment | Before the experiment | After the experiment | |

| Low-temperature experiment | 0.111 | 0.106 | 0.057 | 0.069 | 0.089 | 0.081 | 0.121 | 0.116 |

| High and low temperature impact | 0.123 | 0.112 | 0.065 | 0.031 | 0.095 | 0.052 | 0.132 | 0.085 |

| High-temperature and high humidity | 0.119 |

0.112 | 0.075 | 0.037 | 0.081 | 0.033 | 0.112 | 0.059 |

| Falling | 0.106 | 0.109 | 0.061 | 0.071 | 0.101 | 0.092 | 0.108 | 0.114 |

| Scan vibration | 0.095 | 0.122 | 0.118 | 0.121 | 0.081 | 0.075 | 0.086 | 0.127 |

Before and after the experiment, the sensor was tested by liquid formalin in an experimental chamber with an area of 30m3 to create a formaldehyde concentration of 0.1mg/m3. Among them, after the experiment, the sensor needs to be continuously powered on for 24 hours in an indoor environment before testing.

It can be seen from Table 1 that for the sensors 1# to 4#, the detection accuracy of the sensor before and after the experiment remains unchanged after the drop and scanning vibration experiments, indicating that when they are applied to products such as air conditioners in the later stage, the sensor may be subjected to physical vibration or falling due to the installation, transportation or operation process, and it won't affect the normal use of the sensor. They all show low sensitivity to external physical vibration and other behaviors. At the same time, for the low-temperature experiment, the output characteristics of the sensor can be recovered before and after the experiment, which shows that in the low-temperature environment, both the traditional electrolyte system and the new electrolyte and catalyst formulation system of this study can resist the damage due to low temperatures, thus ensuring the resistance to transport or storage at low temperatures for the sensor. For the high and low temperature impact test, there are different degrees of attenuation for the detection accuracy of commercial sensors 2#, 3# at low temperatures of -20°C and high temperatures of 60°C reaching -52%, -55%, -52% and -36%. This may be caused by the gradual loss of water in the electrolyte inside the sensor during the high-temperature experiment at 60°C and the increase of the electrolyte concentration, which leads to the gradual deterioration of the electrolyte's ability to conduct protons, which in turn leads to irreversible degradation of the detection accuracy of the sensor. For the sensor 1# of this study, the frequent impact of high and low temperature has a limited impact on the new electrolyte system and catalyst formulation system inside the sensor, which also shows that the sensor has good safety performance and reliability at the high and low temperature transient environment. For high-temperature and high-humidity experiments with a temperature of 60°C and humidity of 93%), commercial sensors 2#, 3#, and 4# all show varying degrees of attenuation of detection accuracy, reaching -50%, -59% and -47%. This may be caused by the fact that the sensor is prone to leakages in a high temperature and high humidity environment, resulting in irreversible degradation of the detection accuracy of the sensor. However, the sensor 1# in this study adopts a new electrolyte system, and the high temperature and high humidity environment will not cause the sensor to leak so as to avoid the damage to the proton conductivity caused by high temperatures. Therefore, compared with the current commercial sensors, the formaldehyde sensor in this study can effectively resist the damage of the sensor element caused by the external harsh environment, which plays an important role in improving the long-term working stability and service life of the sensor.

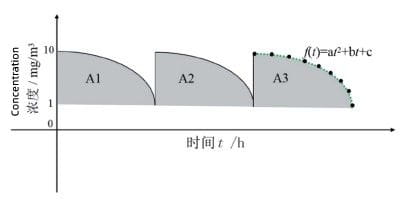

Figure 4 The accelerated aging model of the sensor

3.4 Lifetime acceleration experiment

In order to verify that the sensor element can continue to work normally in an environment with a certain degree of pollution for a long time, an accelerated life experiment is carried out in a high-concentration formaldehyde environment to simulate the accelerated aging of the sensor device, as shown in Figure 4. An environment with a formaldehyde concentration of 10mg/m3 is created in the experimental chamber. After the test time t, when natural attenuation is reduced to 1mg/m3, the formaldehyde concentration is quantitatively supplemented to 10mg/m3, and repeat this process. During the period, the attenuation concentration data is monitored in real time, and the attenuation curve f(t) equals to at2 plus bt plus c; then the accumulated formaldehyde mass data A (mg/m3•h) in the test process simulated by the accelerated life experiment is calculated, as shown in the formula ( 1):

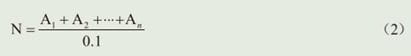

(1) Therefore, compared with the formaldehyde mass concentration (0.1 mg/m3) in the normal experiment, the working life N of the simulated accelerated experiment in this research, as shown in formula (2):

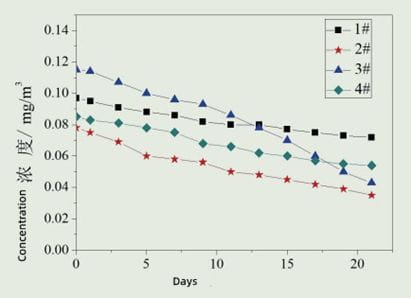

(2) The experimental verified that, under the specific test environment and conditions, the attenuation trend of each cycle is the same, as shown in Figure 4, and the calculated decay curve is: f(t)=0.0016t 2 -0.3286t+8.8202. As shown in Figure 5, the accumulated formaldehyde quality data for 21 days is: A=5544 mg/m3 •h; the detection accuracy attenuation is 26%, and the working life of the sensor in the calculation simulation acceleration experiment is: N=55440 h≈6.33 years. For commercial sensors 2#, 3#, and 4#, after 21 days of accumulative experiments, the detection accuracy attenuation was 55%, 63%, and 36%, all exceeding the reasonable attenuation range of 30%. Therefore, the simulated accelerated working life of the formaldehyde sensor in this study is greater than and equal to 6 years. Compared with the commercial sensors 2#, 3#, and 4#, the sensor in this study can more effectively meet the normal use of the air conditioner during the warranty period.

Figure 5 Accelerated aging test curve of the sensor for 21 days

4. Conclusion

In this article, high-temperature experiments, simulated scene experiments, and anti-interference experiments were carried out based on the formaldehyde sensor element and commercial sensor based on the new electrolyte and anti-interference catalyst formulation. The experimental results show that the new electrolyte and anti-interference catalyst formulation optimized and designed in this experiment can effectively improve its resistance to damage and interference caused by external high temperatures, high humidity, high concentration and other harsh environmental changes, and effectively improve the long-term stability of formaldehyde sensor elements. This has important promotion and significance for the subsequent development of formaldehyde sensors with long service life and good anti-interference ability, and broadening their application in the field of home appliances.

Previous: Research on the Application of Formaldehyde Sensors to Air Conditioning (Part Two)

Next: PM10 Sensors