Abstract: As industrialization progresses, the expansion of heavy-pollution industries such as petroleum, chemicals, power generation, and metallurgy continues. Concurrently, sewage treatment facilities have not met regulatory standards, contributing to worsening air pollution. Traditional PM2.5 detectors are typically bulky, difficult to transport, and less practical. They also have limitations, including high costs, limited real-time performance, and low detection accuracy. This paper proposes a portable, intelligent PM2.5 detector. The system hardware comprises a microprocessor module, input module, display module, wireless transceiver module, and an intelligent detection module based on a laser dust sensor. A software simulator compiles and runs the control program, which calculates particle concentration based on laser scattering principles, enabling precise detection of atmospheric PM2.5 levels. Experimental results demonstrate that the proposed detector responds quickly to PM2.5 pollution, offering high detection efficiency, versatile functionality, and excellent real-time performance. Additionally, its compact form factor ensures ease of use, while its detection accuracy remains superior.

Winter heating in northern regions, combined with the significant increase in motor vehicle numbers, has led to elevated concentrations of particulate matter in the atmosphere. PM2.5 denotes fine particles with a diameter of 2.5 micrometers or smaller. Due to factors such as air pressure, temperature, and meteorological conditions, PM2.5 particles can remain suspended in the atmosphere for extended periods. As the concentration increases, air pollution severity also intensifies. These particles are highly reactive, have a large surface area, and often carry other toxic substances, posing significant health risks.

Currently, the primary methods for detecting PM2.5 include oscillating balance, electrochemical detection, and gravimetric techniques. However, most PM2.5 detectors based on these methods suffer from low sensitivity, limited functionality, and restricted smart capabilities. Large-scale detection instruments, which incorporate multiple particle and gas detection functions, are generally expensive, bulky, and not easily portable, rendering them impractical for use in public spaces, offices, or homes.

Laser technology, a key innovation of the 20th century, has seen rapid advancements since the early 2000s. It has not only transformed data transmission and communication but also achieved significant breakthroughs in measurement and sensing, thanks to its high directivity and coherence. A laser sensor utilizes laser technology for non-contact measurements, offering a wide measurement range, high precision, strong anti-interference capabilities, and fast response times. A laser dust sensor applies the principle of laser scattering to convert scattered light from PM2.5 particles into electrical signals, which are subsequently amplified to show the dust concentration. This study proposes a portable, intelligent PM2.5 detector. Simulation experiments show that the detector provides real-time PM2.5 detection with high precision, versatile applicability, compact size, and portability.

Hardware Structure of the Portable Intelligent PM2.5 Detector:

The portable intelligent PM2.5 detector uses a laser dust sensor as its core module. The overall hardware structure consists of an input module, display module, microprocessor module, wireless transceiver unit, and supporting circuitry.

The main control chip of the microprocessor module incorporates multiple configurable ports, supporting various modes such as PWM, SPI, and digital I/O conversion. The PWM interface of the microprocessor is connected to the laser dust sensor module, which incorporates a 64-bit microprocessor as its main control unit. This processor offers high performance while optimizing power consumption. The chip integrates standard communication interfaces, including PWM, SPI, and digital I/O, ensuring reliable communication.

The NRF24L08 transceiver connects to the main control chip and microprocessor module through the SPI interface. Operating within the 2.5 GHz to 3 GHz frequency range, the communication channel and output power are automatically adjusted and monitored by the main control chip.

The input module is connected to the microprocessor's control chip via a 16-pin double-row socket and digital I/O interface. The LCD module comprises an ICD display and driver circuitry. The LCD element uses a dot-matrix character LCD1605 with an 8-bit data interface and connects to the microprocessor module's digital I/O via a 16-pin double-row socket.

The laser dust sensor, the core module of the portable intelligent PM2.5 detector, consists of two main components: the mechanical assembly and the circuit measurement unit. The mechanical assembly includes an optocoupler isolation circuit and a signal processing unit. The sensor operates on the principle of laser scattering to detect and count PM2.5 dust particles, measure dust concentration, and output a pulse-width-modulated laser signal. The integrated heater increases the air temperature, allowing airflow into the module. Upon exposure to the LED light source, PM2.5 dust particles scatter light, which is then detected by the photoelectric converter. The converter performs photoelectric conversion and amplifies the signal, which is analyzed to determine the size and quantity of the PM2.5 particles. The laser dust sensor can detect particles as small as 1 μm.

The photoelectric converter and laser diode function as the signal transmitter and receiver, respectively. The circuit amplifier amplifies the weak electrical signal, converts it into a digital signal, and sends it to the microprocessor. The frequency output unit converts the measured dust concentration into a corresponding frequency signal. The laser dust sensor operates on the principle of light scattering. When the input light beam interacts with PM2.5 particles, it scatters in all directions. The scattering characteristics of the light are directly correlated with the concentration of dust particles. The photodiode is positioned at a specific angle to detect the scattered light. The dust concentration is then calculated based on the intensity of the scattered light and the principles of light scattering.

To evaluate the performance of the proposed detector system in terms of detection efficiency, accuracy, and overall error, a comparative simulation was conducted. The proposed system was compared with traditional electrochemical and gravimetric detectors. Ten experiments were performed under varying levels of air pollution to assess the detection efficiency of each system. The statistical data from these experiments are shown in Table 1. Analysis of the data reveals that, at high pollution levels, the detection efficiency of all three detectors is comparable. However, at lower pollution levels, the proposed system demonstrates the highest detection efficiency.

|

Pollution Level |

Electrochemical Detector |

Gravimetric Detector |

Detector Proposed in This Paper |

|

I |

1.23 |

1.59 |

0.92 |

|

II |

1.20 |

1.54 |

0.90 |

|

III |

1.18 |

1.24 |

0.87 |

|

IV |

0.98 |

0.95 |

0.82 |

|

V |

0.87 |

0.92 |

0.80 |

|

VI |

0.85 |

0.90 |

0.81 |

|

VII |

0.76 |

0.80 |

0.70 |

|

VIII |

0.69 |

0.79 |

0.68 |

|

IX |

0.52 |

0.62 |

0.52 |

|

X |

0.41 |

0.42 |

0.42 |

To evaluate detection accuracy, the performance of the three detectors was statistically analyzed across 10 pollution levels, as shown in Table 2. The data in Table 2 indicate that the detection accuracy of the electrochemical detector improves with higher pollution levels. In contrast, the gravimetric detector shows lower performance at low pollution levels, but its accuracy increases as the concentration of PM2.5 particles rises. The proposed system outperforms the others, maintaining stable accuracy across all pollution levels, with an average accuracy of 97.84%. In comparison, the electrochemical and gravimetric detectors achieve average accuracy rates of 93.30% and 91.16%, respectively.

Table 2 PM2.5 particle detection accuracy

|

Pollution Level |

Electrochemical Detector |

Gravimetric Detector |

Detector in this Paper |

|

I |

92.35 |

88.96 |

97.36 |

|

II |

91.32 |

86.20 |

97.39 |

|

III |

92.80 |

87.65 |

97.69 |

|

IV |

92.81 |

89.25 |

98.01 |

|

V |

93.02 |

89.31 |

96.97 |

|

VI |

93.25 |

91.36 |

98.09 |

|

VII |

93.65 |

92.54 |

97.63 |

|

VIII |

94.30 |

94.53 |

98.54 |

|

IX |

94.57 |

95.48 |

98.71 |

|

X |

94.88 |

96.31 |

97.96 |

|

Average |

93.30 |

91.16 |

97.84 |

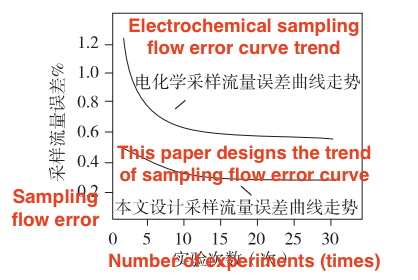

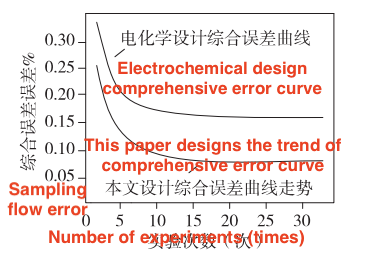

The sampling flow error and overall detection error of the electrochemical detector and the proposed design were compared. The results are shown in Figures 4 and 5.

Figure 4 Comparison of Sampling Flow Errors Between the Two Methods

Figure 5 Comparison of Overall Detection Errors Between the Two Methods

The data clearly indicate that the proposed method offers better control over both errors compared to the traditional design. The sampling flow error remains below 0.5%, and the overall detection error is controlled at less than 0.25%. The experimental data demonstrate that the proposed detector excels in detection efficiency, accuracy, and error management.

As industrialization progresses and the number of motor vehicles increases, air pollution in certain regions has worsened, making haze a significant social issue. Prevention continues to be the primary strategy for addressing haze-related problems. This paper proposes a portable, intelligent PM2.5 detector based on a laser dust sensor. Experimental results show that the proposed detector operates effectively under different pollution conditions, while remaining compact and user-friendly.

Previous: Is Your Air Quality Monitor Trustworthy? Understanding the Importance of Testing Indoor Air Quality

Next: Off-Gassing in Your New Home: What You Need to Know