Humidity sensors play a crucial role in various industries by monitoring moisture levels in the air and ensuring optimal environmental conditions. These sensors contribute to product preservation, energy efficiency, and operational safety across diverse applications, from cold storage management to smart buildings and automotive systems.

This article explores the different types of humidity sensors, their applications in various industries, and how they enhance productivity, safety, and sustainability.

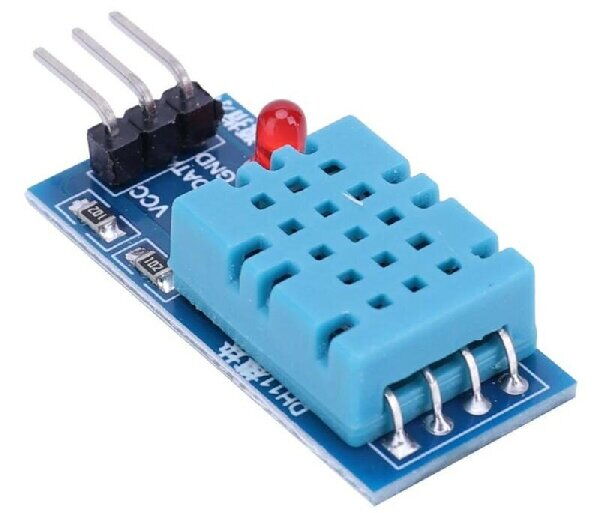

A humidity sensor is a device that detects and measures the amount of water vapor present in the air. Humidity levels influence multiple environmental and industrial processes, making these sensors essential for maintaining stable conditions in controlled settings.

Humidity sensors are categorized into two primary types:

Measure the total water vapor content in the air, regardless of temperature.

Typically used in industrial and scientific applications where precise humidity measurement is required.

Measure the amount of water vapor in the air relative to the temperature.

More commonly used in HVAC systems, smart buildings, and consumer electronics.

Humidity sensors have widespread applications across industries. Below are some of the key sectors where these devices play a critical role.

Cold storage facilities house temperature-sensitive products such as food, beverages, pharmaceuticals, and medical supplies. Controlling humidity levels is crucial for maintaining product quality and extending shelf life.

Excessive humidity in cold storage environments can cause condensation, leading to mold growth and food spoilage. Humidity sensors help maintain optimal conditions, preventing moisture-related damage.

Many medicines and vaccines require strict humidity control to ensure their efficacy. Humidity sensors contribute to regulatory compliance by maintaining precise environmental conditions.

These sensors support automated audits, ensuring that temperature and humidity levels adhere to safety regulations. They also assist in predictive maintenance by identifying issues before they compromise storage conditions.

By integrating humidity sensors with temperature monitoring systems, businesses can enhance regulatory compliance, improve product safety, and reduce waste.

Modern smart buildings rely on automation and data-driven insights to improve occupant comfort and energy efficiency. Humidity sensors are essential components of Building Management Systems (BMS), allowing facility managers to optimize environmental conditions.

HVAC systems equipped with humidity sensors can adjust air conditioning or heating settings based on real-time data, creating a comfortable indoor environment while minimizing energy consumption.

Museums, galleries, and archives require stable humidity levels to prevent damage to artifacts, paintings, and historical documents. By tracking humidity fluctuations, institutions can safeguard their collections from deterioration.

Excess humidity can lead to mold growth and poor indoor air quality. Humidity sensors enable proactive ventilation adjustments to maintain a healthier indoor environment.

By incorporating humidity sensors into facility management strategies, businesses can improve workplace comfort, protect assets, and reduce energy costs.

Humidity sensors are increasingly used in remote monitoring and industrial asset management, enabling businesses to transition from preventive to predictive maintenance strategies.

Humidity sensors installed in pumps, compressors, and electrical cabinets help detect moisture buildup, preventing equipment failures caused by corrosion or condensation.

High humidity levels in data centers can lead to electrical failures and hardware malfunctions. Humidity sensors help maintain ideal conditions, ensuring optimal server performance and longevity.

In critical infrastructure such as power plants, humidity sensors play a vital role in detecting leaks before they cause significant damage. By providing real-time data, they help prevent costly repairs and operational downtime.

These sensors contribute to extending the lifespan of assets and optimizing maintenance schedules, reducing operational disruptions.

In agricultural settings, maintaining proper humidity levels is crucial for crop health and yield optimization. Humidity sensors assist farmers in regulating greenhouse environments and protecting sensitive plants.

Some crops require specific humidity levels to thrive. Humidity sensors enable precise climate control, promoting healthy plant growth and reducing water usage.

High humidity in livestock facilities can lead to respiratory issues in animals. Monitoring and adjusting humidity levels contribute to healthier livestock and improved productivity.

While humidity sensors primarily measure air moisture, they can be integrated with soil sensors to optimize irrigation schedules, preventing overwatering or drought stress.

By using humidity sensors in agriculture, farmers can enhance crop quality, conserve resources, and increase overall efficiency.

The automotive industry incorporates humidity sensors in both manufacturing processes and vehicle systems to enhance safety and comfort.

Modern cars use humidity sensors in HVAC systems to adjust cabin humidity and prevent windshield fogging. This improves visibility and ensures a comfortable driving experience.

EV battery systems are highly sensitive to moisture. Humidity sensors monitor and maintain optimal humidity levels, preventing condensation-related battery failures.

During automotive assembly, maintaining proper humidity is essential for painting, welding, and material adhesion processes. Humidity sensors help manufacturers ensure consistent product quality.

By integrating humidity sensors into vehicle systems and production lines, automakers enhance passenger comfort, safety, and manufacturing efficiency.

As industries continue to embrace automation and smart technology, humidity sensors will play an increasingly vital role in enhancing efficiency, safety, and sustainability. Future developments in humidity sensing technology include:

The rise of the Internet of Things (IoT) is driving the development of wireless humidity sensors, enabling real-time remote monitoring and cloud-based analytics.

Advances in sensor technology will lead to smaller, more accurate humidity sensors that can be seamlessly integrated into wearable devices, medical instruments, and consumer electronics.

Machine learning algorithms will enhance the predictive capabilities of humidity sensors, helping industries anticipate and mitigate environmental risks before they occur.

The next generation of sensors will focus on low-power consumption and self-sustaining energy sources, improving battery life and sustainability.

With ongoing innovations, humidity sensors will continue to revolutionize industries, driving smarter operations and improved environmental control.

Humidity sensors have become indispensable across multiple industries, ensuring product quality, enhancing comfort, optimizing energy efficiency, and preventing equipment failures. From cold storage management and smart buildings to industrial maintenance and automotive applications, these sensors provide critical real-time data that enables proactive decision-making.

As technology advances, humidity sensors will become even more sophisticated, supporting the evolution of smart industries and sustainable practices. Businesses that leverage these innovations will benefit from improved efficiency, reduced costs, and greater environmental responsibility.

By adopting humidity sensors in their operations, industries can move toward a more resilient and intelligent future.

Previous: The Application and Importance of Dust Sensors in Modern Environments

Next: What is HCHO Air Quality?