Carbon dioxide (CO2) sensors are vital in a range of applications, from maintaining indoor air quality to optimizing industrial processes. However, like all precision instruments, CO2 sensors can drift over time, leading to inaccurate readings. Regular calibration is the key to ensuring their reliability and accuracy. This article explores the importance of calibrating CO2 sensors, the methods involved, and answers common questions about maintaining these essential devices.

Calibration is the process of adjusting a CO2 sensor to align with a known reference point, ensuring its readings are precise and consistent. Over time, CO2 sensors, especially those based on non-dispersive infrared (NDIR) technology, experience a phenomenon called "drift." Drift occurs as the infrared light source and detector inside the sensor degrade, leading to slight inaccuracies in measuring CO2 levels.

NDIR sensors measure CO2 levels by detecting the amount of infrared light absorbed by CO2 molecules. Over time, the light source and detector age, causing a reduction in light intensity and accuracy. Without calibration, these sensors may report progressively lower CO2 concentrations than the actual levels.

Ensures precise CO2 measurements critical for applications like indoor air quality monitoring, greenhouses, and safety systems.

Regular calibration extends the operational life of the sensor.

Helps meet regulatory standards in industries that rely on accurate CO2 monitoring.

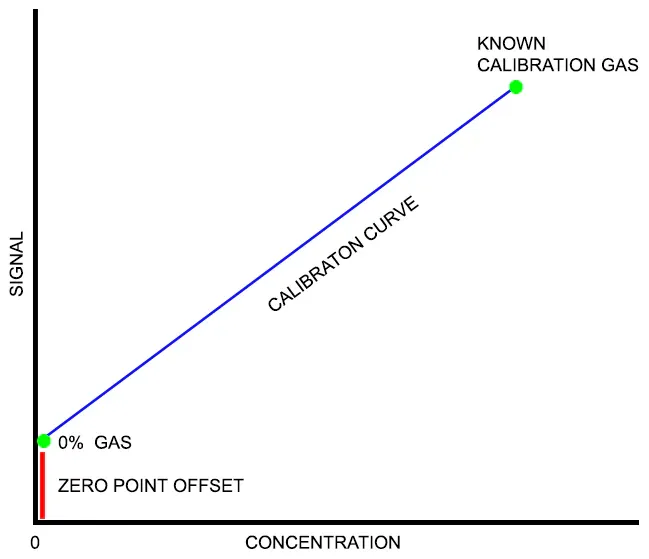

Calibration involves exposing the CO2 sensor to one or more gases with known CO2 concentrations. By comparing the sensor’s readings with the known values, adjustments are made to correct any discrepancies.

The sensor is placed in an environment with a reference gas, such as 400 ppm (fresh air) or a higher concentration for span calibration.

The difference between the sensor’s readings and the reference values is stored in its memory.

The sensor automatically applies the calculated offset to its measurements, ensuring accurate results.

Two primary methods are used for calibrating CO2 sensors:

This method involves setting the sensor to recognize a baseline CO2 concentration, typically fresh air (approximately 400 ppm).

It is ideal for ensuring the sensor can detect CO2 levels accurately at low concentrations.

Span calibration adjusts the sensor's readings at higher CO2 concentrations, such as 2,000 ppm.

This method is crucial for applications requiring precise measurements across a wide range of CO2 levels.

Place the CO2 sensor module in a well-ventilated room to avoid interference from residual gases.

Navigate to the device’s configuration menu (e.g., Settings > Manage My Home > Sensor Configurations).

Choose zero-point or span calibration based on the desired reference level.

Launch the manual calibration process and wait for the sensor to adjust.

Yes, all CO2 sensors require periodic calibration to ensure accurate readings. For NDIR sensors, this involves comparing the sensor’s measurements against a reference gas that is unaffected by temperature or pressure variations.

Most CO2 sensors last between 5 to 7 years, with some newer models reaching up to 10 years. The lifespan depends on usage, environmental factors, and maintenance practices.

A simple way to test the sensor is to take it outdoors, where CO2 levels should measure around 400 ppm in fresh air. Another method is to blow into the sensor, as human breath contains about 3,000 ppm CO2. A functioning detector should quickly register this increase and return to normal levels once exposure stops.

ABC adjusts the sensor’s baseline CO2 readings automatically over time.

Pros: Minimal user intervention; suitable for sensors in environments with periodic fresh air exposure.

Cons: May lead to inaccuracies in spaces with consistently high CO2 levels, such as industrial or crowded settings.

Involves calibrating the sensor with known gas concentrations.

Pros: High precision; ideal for controlled environments.

Cons: Requires periodic manual effort and specialized equipment.

Perform routine tests using known CO2 concentrations to verify the sensor’s accuracy.

Avoid exposing the sensor to extreme temperatures, humidity, or contaminants, which can accelerate drift.

Ensure the sensor’s firmware is up-to-date for optimal performance.

If the sensor shows consistent inaccuracies despite calibration, consider replacing its light source or detector.

Calibrating CO2 sensors is essential for maintaining accuracy, reliability, and compliance in various applications. Whether through manual methods or automated processes like ABC, regular calibration ensures these sensors perform optimally throughout their lifespan. By understanding the importance of calibration and following proper maintenance practices, users can maximize the effectiveness of their CO2 monitoring systems while ensuring safety and efficiency in their operations.

Previous: CO2 Sensor vs. VOC Sensor: What's the Difference?

Next: Is Your Air Quality Monitor Trustworthy? Understanding the Importance of Testing Indoor Air Quality