Dust sensors are primarily employed to measure the concentration of particulate matter in various environments. As demands for improved living and working conditions rise, the hazards posed by industrial dust to human health have become increasingly evident. Construction sites, owing to large-scale operations, often generate airborne dust, serving as a principal contributor to urban dust pollution. Installing dust monitoring systems at construction sites can effectively enhance the dust environment. When the concentration of airborne dust from operations reaches a certain threshold, appropriate dust mitigation measures can be taken to reduce dust pollution. The use of optical scattering principles in dust sensors is prevalent among both domestic and international manufacturers, distinguishing between conventional optical scattering and laser-based optical scattering methods. Laser-based optical scattering has largely supplanted conventional optical scattering methods in Europe, America, and Japan due to its superior repeatability and stability.

Operating Principles of Dust Concentration Sensors

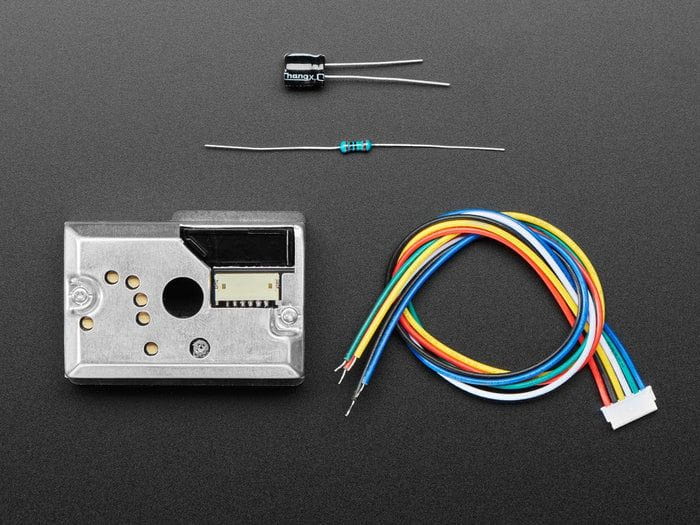

Dust sensors utilize advanced mechanisms to detect PM2.5 levels. The PM2.5 detection unit within the dust sensor employs particle counting principles to sensitively detect dust particles with a diameter greater than 0.5μm. The operational principles encompass light absorption, light scattering, beta-ray radiation, microcomputer laser technology, and alternating current electrostatic induction. Five primary rapid detection methods are employed: light scattering, beta-ray radiation, microbalance weighing, electrostatic induction, and piezoelectric balance. Microbalance weighing instruments are largely monopolized by a few American companies, resulting in high costs and maintenance fees. Electrostatic induction instruments are generally utilized for detecting leaks in cloth bag dust collectors. The utilization of piezoelectric balance methods is more complex, with few manufacturers available.

Functional Specifications of Dust Concentration Sensors

- Data Precision: Detection through laser principles and industrial-grade photoelectric induction.

- High Resolution: Detects particle diameters ≥ 0.3μm, with a sensitivity of 0.001mg/m³.

- Measures PM2.5, PM10, TSP (Total Suspended Particulates).

- Stable Performance: Adaptable to varying atmospheric environments and dust compositions, featuring independent parameter coefficient adjustments.

- Data Transmission: Supports 485 (Modbus standard protocol), RS232, UART output, and offers switch output for integration with outdoor audiovisual alarm systems, among others.

- Intelligent Monitoring: Real-time monitoring of sensor metrics with prompt user feedback on anomalies.

Applications and Fields of Dust Concentration Sensors

- Ideal for determining dust concentrations in production sites of industrial and mining enterprises.

- Monitors inhalable particulate matter in public spaces at hygiene and epidemic prevention stations.

- Used by environmental protection departments for atmospheric airborne dust measurements and pollution source investigations.

- Implemented in urban smoking control.

- Deployed for scientific research and on-site testing of filter material performance.

- Measures on-site dust concentrations and monitors dust concentrations at exhaust outlets.

- Applied in pharmaceutical manufacturing testing.

- Critical for occupational health and safety evaluations.

- Manages clean air requirements in factories involving precision instruments, testing equipment, electronic components, as well as food and pharmaceutical manufacturing processes.

- Essential for research institutions in fields such as meteorology, public health, industrial hygiene engineering, and atmospheric pollution studies.

- Detects dust in construction sites or areas affected by explosions; monitors exposed conditions at work sites.

- Assesses indoor air quality.

In comparison to automatic atmospheric monitoring stations, dust monitoring, smart city monitoring stations, air micro-stations, and similar air quality monitoring devices are cost-effective, easy to deploy, and have become indispensable auxiliary tools for environmental inspection and supervision by various government levels. The data quality of these monitoring devices is closely tied to the core component they use—dust sensors.

Previous: Application of CO2 Sensors in Ventilation Control Systems

Next: The Role of Humidity Sensors in Diverse Industries